Triple Volute Screw Press

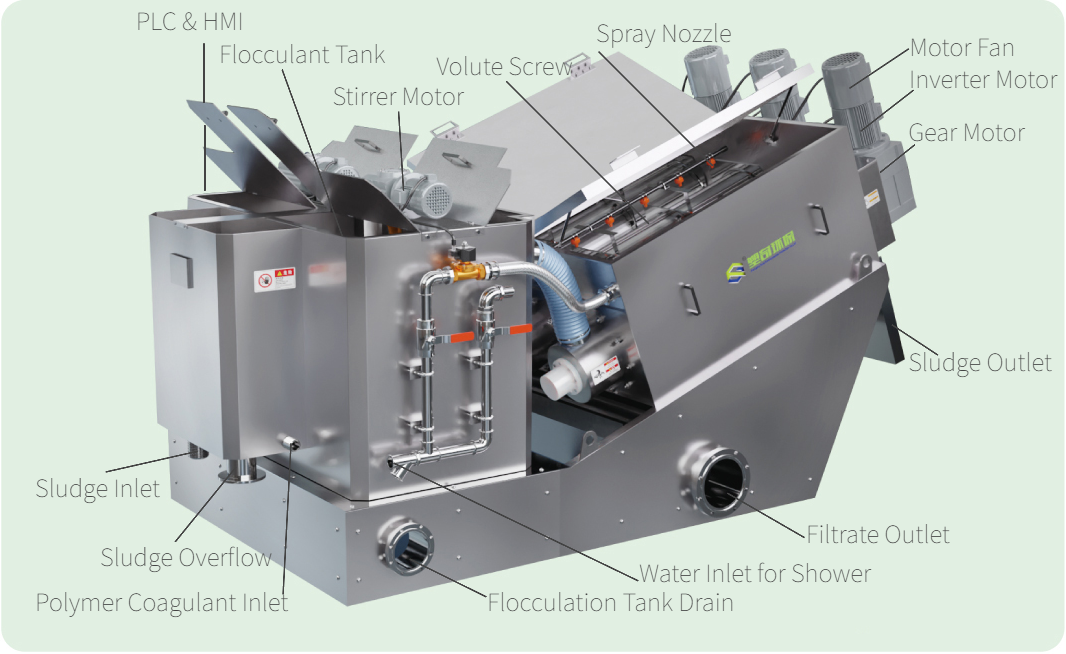

Triple volute screw press is a screw press with 3 set screw shafts. It integrates a full-automatic PLC control cabinet, sludge concentration and dehydration body and a flocculation tank. It can achieve efficient flocculation under the condition of fully automatic operation and continuously complete the sludge concentration and dehydration work. The collected filtrate is refluxed or discharged, and the dewatered sludge is discharged.

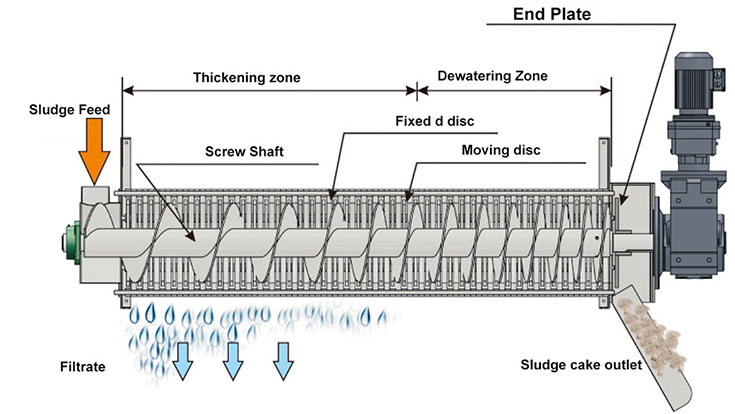

The main body of the volute screw press is composed of multiple fixed rings, washers and moving rings. The screw shaft runs through it to form a filtering device. The front section is the concentration section and the rear section is the dewatering section. The volute screw press replaces the traditional filter cloth and centrifugal filtration methods with a unique and delicate filter structure.

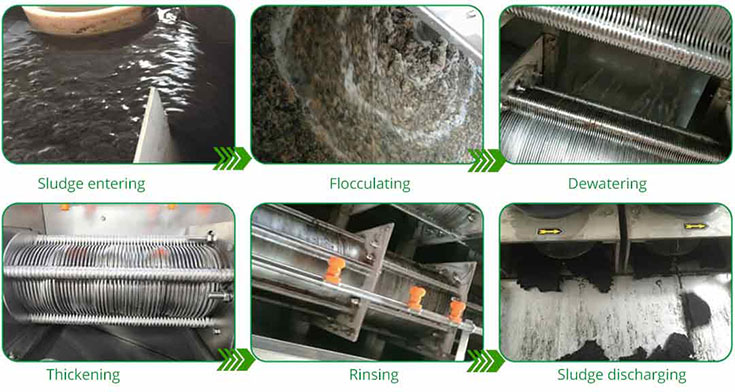

Concentration: When the screw shaft rotates, the multiple moving and fixed rings (plates) located on the periphery of the screw shaft move relative to each other. Under the action of gravity, water is filtered out from the gap between the relatively moving rings (plates) to achieve fast sewage

Dehydration: The condensed sludge moves upwards and downwards with the rotation of the screw shaft, the pitch of the screw shaft gradually becomes smaller, the gap between the rings gradually becomes smaller, and the space of the spiral cavity also continues to shrink. Below, the internal pressure is gradually increased. With the continuous operation of the screw shaft, the water in the sludge is squeezed and discharged, and the solid content of the filter cake is continuously increased, and the continuous dehydration of the sludge is finally achieved.

Automatic cleaning: The rotation of the screw shaft promotes the continuous rotation of the moving ring. The device relies on the movement between the fixed ring and the moving ring to achieve a continuous self-cleaning process, thereby avoiding the problem of blockages commonly existing in traditional dehydrators.

• Concentration and dehydration of various sludge in municipal sewage treatment plants

• Industrial wastewater treatment plants (concentration and dewatering of various sludges in papermaking, tanning, textile, mining)

• Disposal of livestock manure in the livestock industry

• Recovery of drilling sludge

• Treatment of waste oil and sludge in refinery

• Treatment of sludge in the food processing industry

- Power saving: less than 5% of the centrifuge

- Water saving: less than 0.1% of belt filter press

- Provincial Medicine: 65% on average

- Save space: save 60% of investment in dehydration room

- Non-clogging: suitable for oily fiber sludge

- Low operating cost: less than 40% of belt filter press, less than 20% of centrifugal dewatering machine

Capacity

| Model No. | Dewater Capacity(kg/hr) | Sludge Flow Rate(m³/hr) | ||||||

| Low Concentration | High Concentration | 10g/l | 20g/l | 25g/l | 50g/l | |||

| SQDL253 | 45 | 90 | 4.5 | 4.5 | 3.6 | 1.8 | ||

| SQDL303 | 90 | 180 | 9 | 9 | 7.2 | 3.6 | ||

| SQDL353 | 150 | 300 | 15 | 15 | 12 | 6 | ||

| SQDL403 | 240 | 480 | 24 | 24 | 19.2 | 9.6 | ||

| Note: The sewage concentration is less than 10000mg/L, it is recommended to carry out sedimentation and concentration treatment; the sewage concentration is greater than 25000mg/L, it is recommended to carry out dilution treatment. | ||||||||

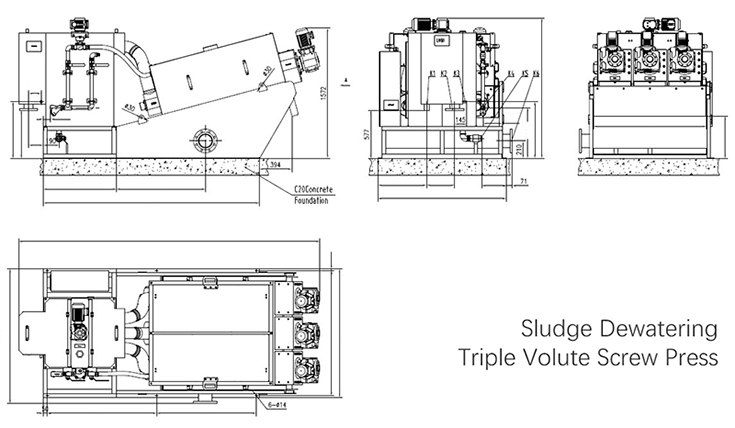

| Model | Dimension | Screw press Dimension (mm) | Net Weight (kg) | Running Weight (kg) | ||||

| Length (mm) | Width (mm) | Height (mm) | ||||||

| SQDL303 | 3700 | 1650 | 1700 | DN300X2220 | 1750 | 3030 | ||

| SQDL353 | 4120 | 1770 | 1850 | DN350X2480 | 2800 | 4830 | ||

| SQDL403 | 4790 | 2600 | 2250 | DN400X3100 | 5400 | 9710 | ||

| Model. No. | Power(kw) | Cleaning water pressure | Cleaning water consumption (L/h) | Maintenance frequency | ||||

| Screw Drive | Stirrer Drive | Amount | ||||||

| SQDL253 | 0.55x3 | 0.55x1 | 2.2 | ﹥2kg/cm² | 174 | 10minutes/day | ||

| SQDL303 | 0.75x3 | 0.75x1 | 3 | 279 | ||||

| SQDL353 | 1.1x3 | 1.1x1 | 4.4 | 378 | ||||

| SQDL403 | 1.5x3 | 1.5x2 | 7.5 | 345 | ||||