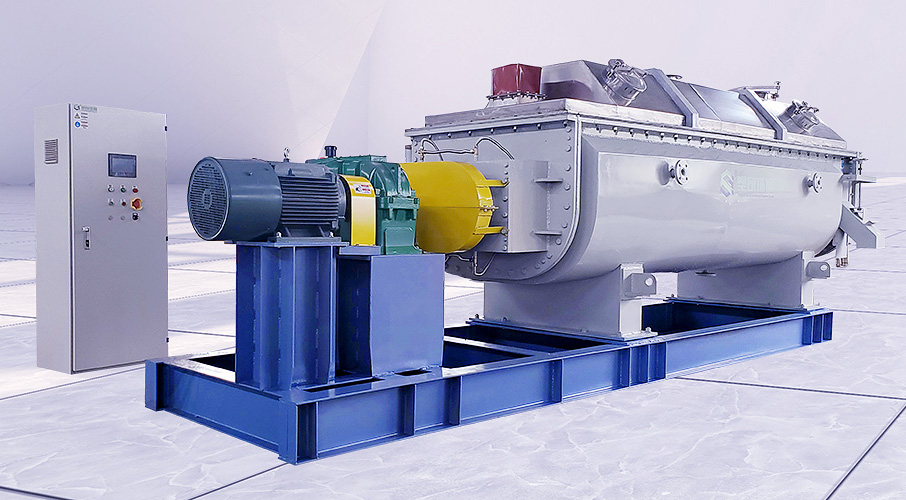

Hollow Paddle Dryer is a continuous indirect heating device for drying (cooling) materials, such as dried sludge from sewage dewatering machine( take volute screw press for example)

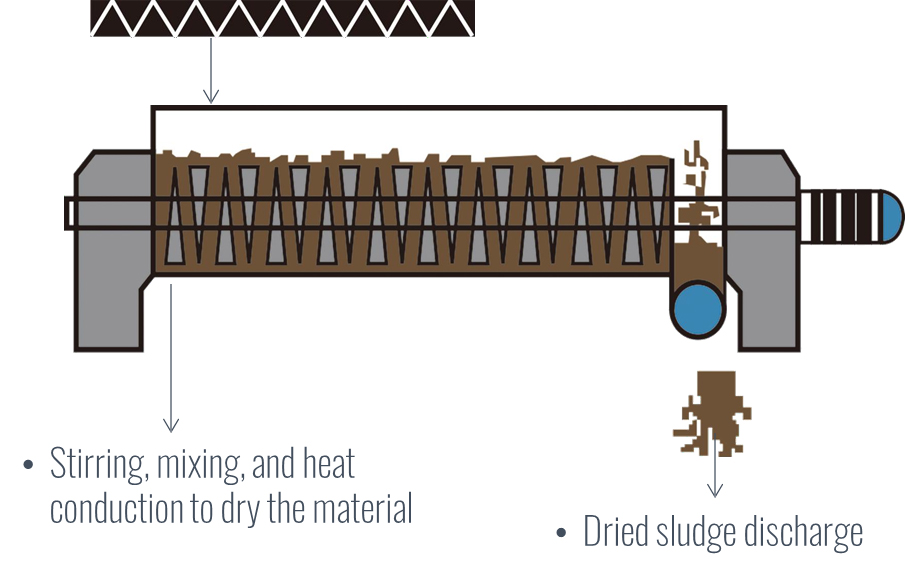

Working Principle

- Hollow Paddle Dryer is a continuous indirect heating device for drying (cooling) materials

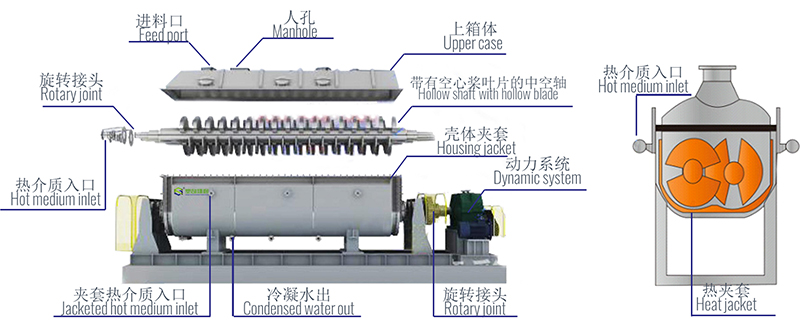

- There are two parallel rotary shafts inlaid with interlaced paddles in the jacket shell

- Each shaft is inlaid with hollow fan-shaped paddles staggered at a certain interval, and the shaft rotates at a low speed

- The heat medium enters the hollow rotary shaft and paddle through the rotary joint installed at the end of the rotary shaft

- After heat transfer and drying, it is discharged out of the machine through the rotary joint

- Heat medium will also be introduced into the jacket

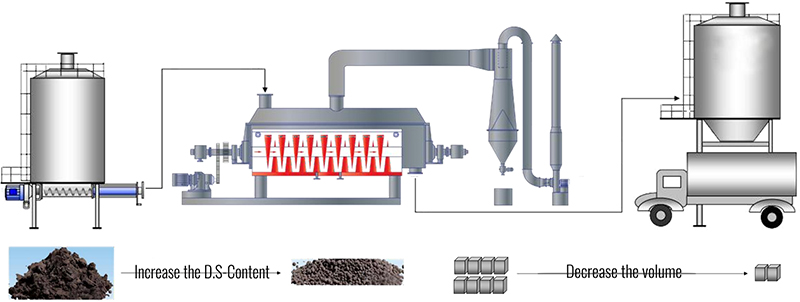

Technical Process

Hollow Paddle Dryer Structure and Main parts BOM

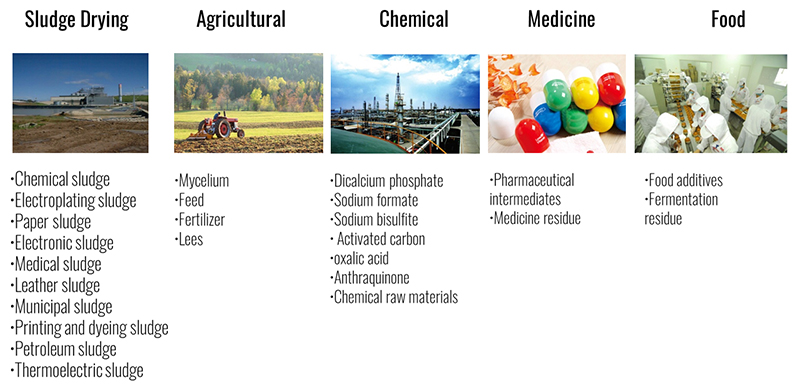

Application

On-site Case

Model Selection Table

|

Model No. |

KJG-20 |

KJG-30 |

KJG-40 |

KJG-50 |

|

Heat transfer area (㎡) |

20 |

30 |

40 |

50 |

|

Effective volume (㎡) |

1.5 |

3.5 |

5 |

7 |

|

Rotation Speed (rpm) |

15-23 |

10-15 |

10-15 |

10-15 |

|

Power (kw) |

11 |

22 |

30 |

37 |

|

Total Length (mm) |

5423 |

7220 |

6682 |

7250 |

|

Total Width (mm) |

1218 |

1450 |

2075 |

2030 |

|

Total Height (mm) |

1650 |

2190 |

2376 |

2548 |

|

Vessel Length (mm) |

3000 |

4000 |

4000 |

4500 |

|

Vessel Width (mm) |

850 |

1100 |

1276 |

1400 |

|

Center Height (mm) |

980 |

1000 |

950 |

1050 |

|

Distance of material inlet & outlet(mm) |

2550 |

3800 |

4420 |

4950 |

|

Air Inlet (N |

1 |

1.2 |

1.2 |

1.5 |

|

Water Inlet O |

1 |

1.2 |

1.2 |

1.5 |

|

Model No. |

KJG-60 |

KJG-70 |

KJG-80 |

KJG-100 |

|

Heat transfer area (㎡) |

60 |

70 |

80 |

100 |

|

Effective volume (㎡) |

8.5 |

10 |

12 |

15 |

|

Rotation Speed (rpm) |

10-15 |

10-15 |

10-15 |

10-15 |

|

Power (kw) |

37 |

45 |

55 |

55 |

|

Total Length (mm) |

7800 |

8050 |

9000 |

9800 |

|

Total Width (mm) |

2030 |

2424 |

2000 |

2500 |

|

Total Height (mm) |

2677 |

2700 |

2700 |

2800 |

|

Vessel Length (mm) |

5500 |

5000 |

5500 |

6000 |

|

Vessel Width (mm) |

1516 |

1650 |

1650 |

1822 |

|

Center Height (mm) |

1200 |

1350 |

1350 |

1400 |

|

Distance of material inlet & outlet(mm) |

5000 |

4500 |

5000 |

5500 |

|

Air Inlet (N |

1.5 |

1.5 |

2 |

2 |

|

Water Inlet O |

1.5 |

1.5 |

2 |

2 |

|

Model No. |

KJG-120 |

KJG-160 |

KJG-200 |

KJG-220 |

|

Heat transfer area (㎡) |

120 |

160 |

200 |

220 |

|

Effective volume (㎡) |

18 |

23 |

32 |

34 |

|

Rotation Speed (rpm) |

10-15 |

6-12 |

6-12 |

6-12 |

|

Power (kw) |

75 |

110 |

110 |

132 |

|

Total Length (mm) |

10560 |

12000 |

12050 |

12500 |

|

Total Width (mm) |

2650 |

2950 |

3300 |

3300 |

|

Total Height (mm) |

3050 |

3300 |

3700 |

3700 |

|

Vessel Length (mm) |

6000 |

7000 |

7000 |

7440 |

|

Vessel Width (mm) |

1978 |

2324 |

2450 |

2450 |

|

Center Height (mm) |

1325 |

1350 |

1525 |

1400 |

|

Distance of material inlet & outlet(mm) |

5500 |

6500 |

6500 |

7000 |

|

Air Inlet (N |

2 |

2 |

2 |

2 |

|

Water Inlet O |

2 |

2 |

2 |

2 |